Oil and Gas

- Accueil

- |

- Industries

- |

- Energy & Environment

- |

- Oil and Gas

Oil and gas industries: ISO 13679 test benches for premium connection testing

PINETTE PEI is an internationally recognized supplier of test benches for premium connection testing (ISO 13679 standard). Through these test benches, we put our expertise in industrial control and testing machines and systems at the service of oil and gas well equipment suppliers (OCTG).

The oil and gas industry is divided into “upstream” and “downstream” activities. In the upstream sector, three types of tubular products with threaded connections are used, divided into two groups:

DRILL PIPES

Drill pipes are steel tubes with threaded ends used to drill into the ground until the pocket containing the hydrocarbons is reached.

CASING TUBES AND TUBING

Casing tubes and production tubes are known as OCTG (Oil Country Tubular Goods) products:

- Casing tubes are used to stabilize boreholes. They are important structural components used to consolidate well walls.

- Production pipes are used to transport crude oil and natural gas from the pockets where the hydrocarbons are located to the pipelines on the surface.

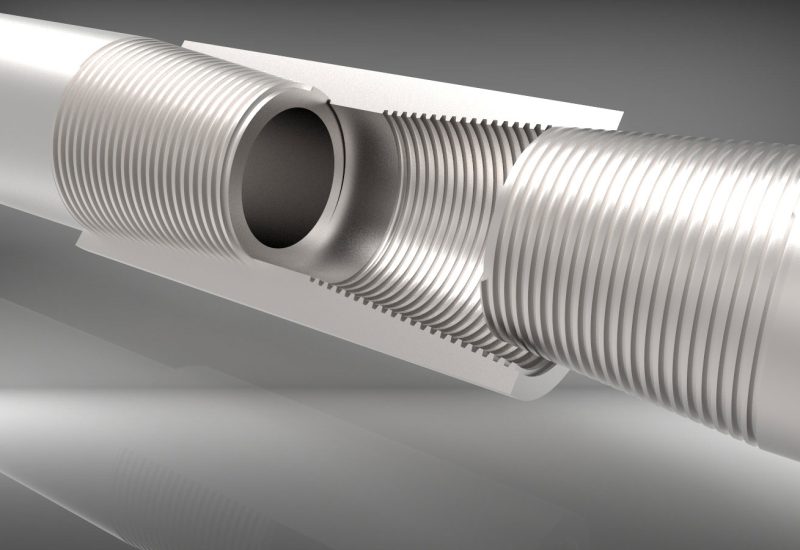

These steel tubes, threaded at both ends, are joined by fittings or integral connections to form a production column, the pipe through which hydrocarbon fluids are extracted to the surface. These essential connections are therefore subject to qualification programs such as ISO 13679.

The test benches designed and supplied by PINETTE PEI enable these qualification tests to be carried out on a full scale.

Premium threaded connections for tubular products.

To meet ever more demanding safety standards and extreme drilling conditions, OCTG product suppliers have designed premium connections that differ from conventional PLC connections in :

- A torque shoulder

- A metal-to-metal seal to replace the elastic joint

- Thread shapes optimized for enhanced performance

The International Organization for Standardization (ISO) has drawn up 2 standards to define and govern structural test procedures on premium connections:

- ISO 13679: Test procedures for casing and production pipe connections

- ISO 12835: Qualification of casing connections for thermal wells

Test benches for premium connection testing

The test rigs designed, manufactured and supplied by PINETTE PEI meet the requirements of these standards, as well as those of increasingly difficult drilling conditions. Our equipment goes even further, thanks to the simultaneous application of several stresses: tension, compression, bending and simulation of HPHT (high-pressure, high-temperature) conditions.

To complete these test programs, premium connections must also undergo fatigue resistance tests via multiple screwing and unscrewing cycles. All this enables us to reproduce the most extreme conditions to which connections can be subjected in wells, and to assess the sensitivity of connections to frictional wear.